Have you ever noticed how the bacon on your bacon burger is consistently of the same colour, shape, and size? Why do we never see burnt bacon I burn bacon at home all the time? The answer is an advanced 3D Scorpion Vision system!

16 Cameras Looking at 1300 Rashers of Bacon Per Minute

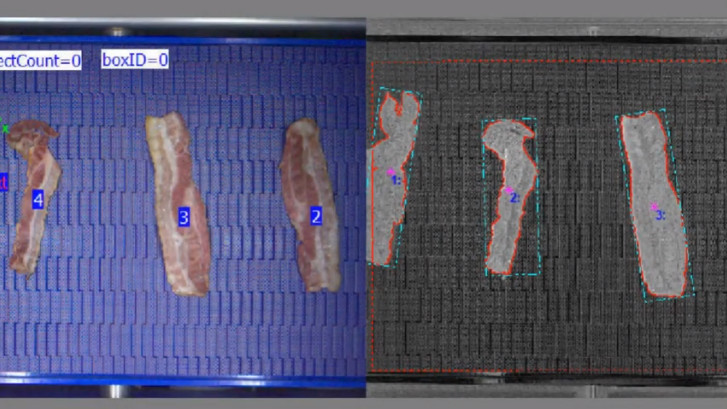

Scorpion Vision Ltd has recently provided a high-speed bacon rasher inspection and counting system for the industry.

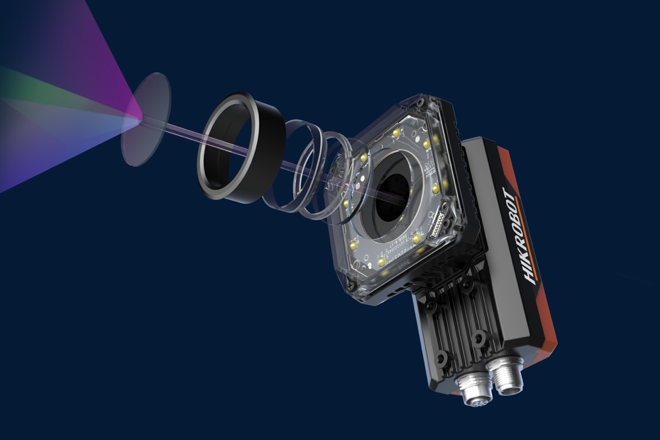

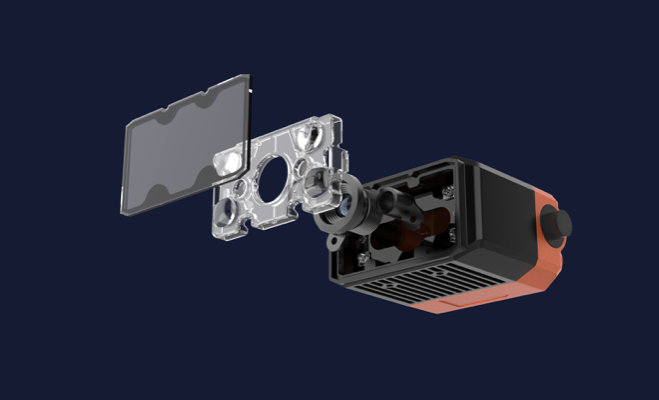

The inspection system uses 16 individual Scorpion Stinger 2D cameras to inspect 16 lines of bacon rashers moving on a conveyor that is travelling at 14 metres per minute. That literally translates to 1300 rashers of bacon per minute or nearly 500,000 bacon rashers in 24 hours from one factory.

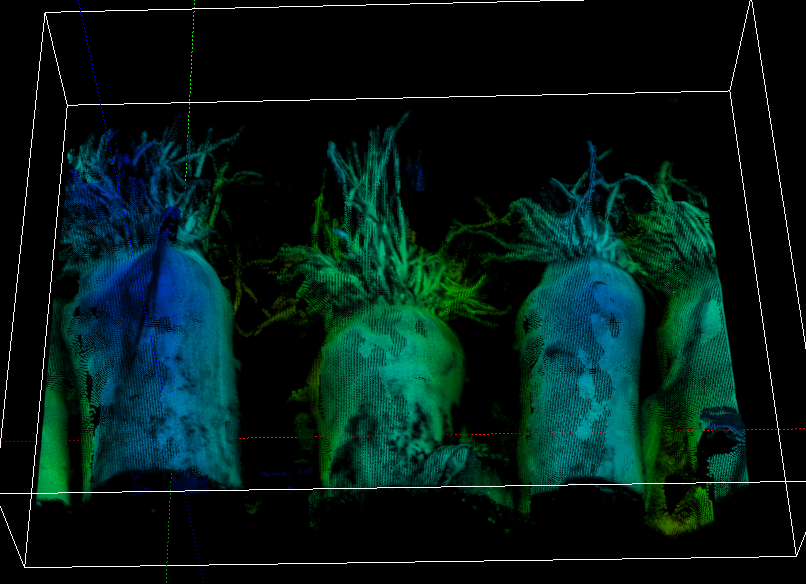

The camera-based system actually looks at every individual bacon rasher and measures it to ensure that it meets the criteria set by the manufacturer. If it does meet the criteria, the rasher is then allowed to drop into a container along with a pre-set number of other rashers that have also passed the inspection. The vision system knows when the container is full as it has counted everything that goes into it. At this point, the container is released to be sealed and sent off to be dispatched.

If, on the other hand, the rasher does not pass the inspection, the vision system identifies it for rejection. Its position on the conveyor belt is recorded and the item is tracked to the end of the conveyor where it is pushed off the conveyor by an air jet.

It’s More Complex Than It Sounds

The enabling technology for this application is the Scorpion Vision bacon counting system as it has to manage a large number of complex scenarios at very high speed.

For the customer, it is critical that the number of rashers in each box is correct, with no under-counts and a maximum of 1 over-count.

Massive Production Gains by Minimising ‘Giveaway’

The gain for this bacon producing factory is significant because in the past, bacon was placed into the containers by hand and its weight was roughly measured. This resulted in what the industry calls ‘giveaway’. So, the move to a system that counted individual rashers, whilst also measuring them to improve quality, makes complete sense. Above all, it saves money as well!

Below is a brief video – look out for the small bits of bacon being pushed off the end of the conveyor by the air jet.

Reposted from Scorpion Vision Ltd Blog dated 12th January 2019

https://www.scorpionvision.co.uk/blog/the-scorpion-vision-bacon-inspector