Scorpion Vision Ltd built their first tortilla flatbread inspection system in the UK 10 years ago. The customer’s business has grown since then as a result and they are now delivering multiple systems.

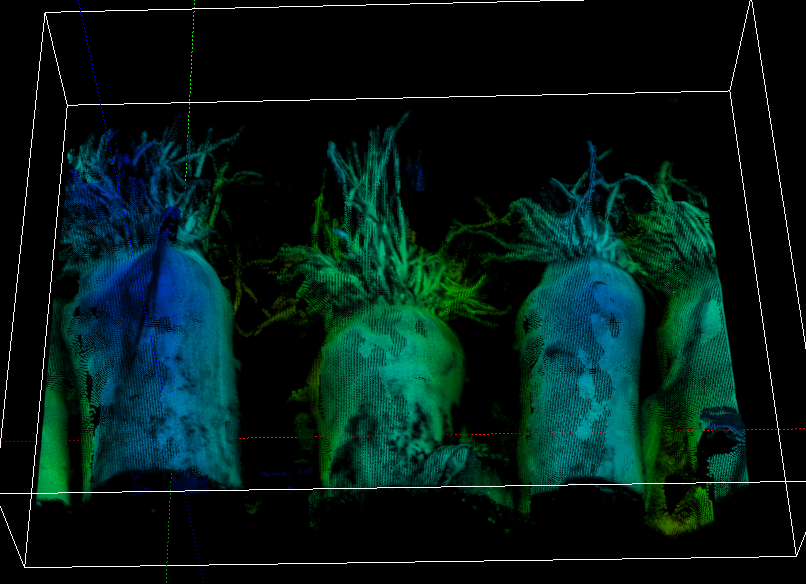

The system is placed in-line in a tortilla production line. The product is fed into the inspection system at a rate of up to 45,000 products per hour. The inspection system then locates each product and measures it, looking for torn, deformed or too large or or too small. When it identifies any of these conditions, the vision system sends a signal to series of pneumatic ejectors and the flawed product is individually removed using air jets.

100% inspection, 100% of the time.

This system can be retrofitted to inspect other kinds of products flowing quickly on a conveyor belt.

Reposted from Scorpion Vision Ltd Blog dated 12th February 2020

https://www.scorpionvision.co.uk/blog/inspecting-45000-tortillas-per-hour