Robotic Labelling of Stilton Cheese wedges is challenging due to their varying size and shape. 3D machine vision is the solution.

Scorpion Vision Ltd worked with Stilton Cheese producer Long Clawson Dairy to solve an age old problem. Quite simply, the variable and odd shaped cheese portions are difficult to label automatically. Using a traditional mechanical labelling system, the labels were not applied in a repeatable fashion on the wedges and Clawson were reworking up to 80% of their labelled cheese products, which was expensive and inefficient.

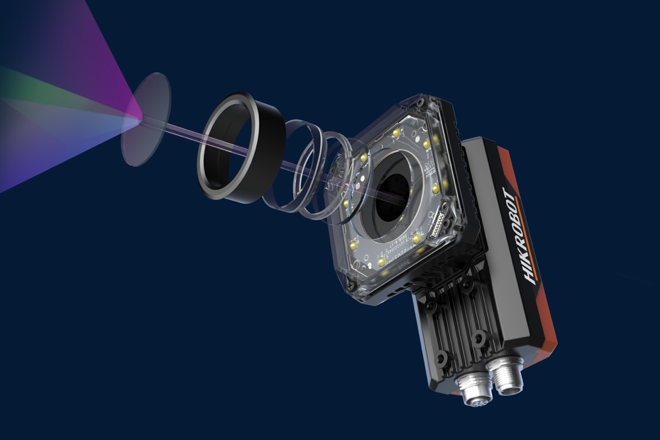

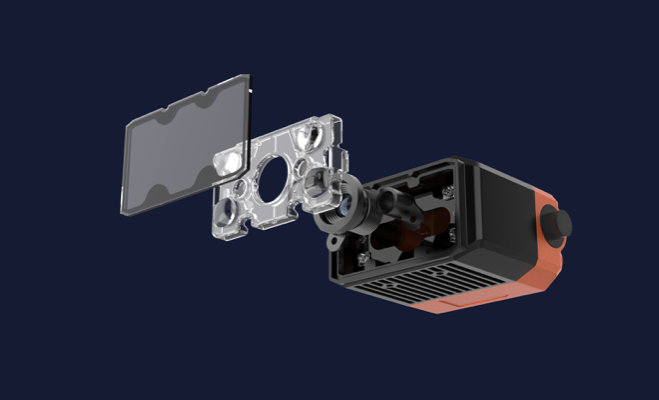

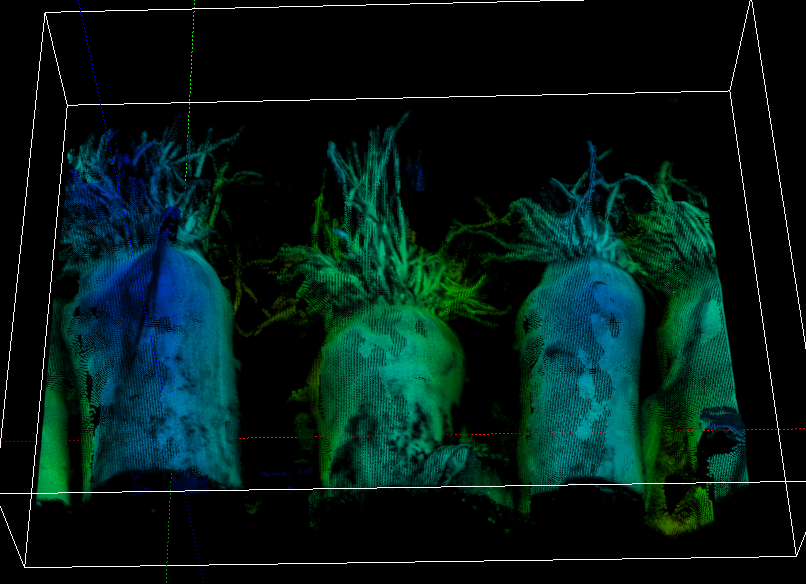

Scorpion Vision technology was used to develop a vision system that created a mathematical 3D model of each piece of cheese as it travelled under the cameras, along a conveyor belt.

The model was used to identify the longest side where the label was destined to be placed, straight and level. Once this is done (in a few hundred milliseconds), the coordinates are sent to the robot system along with the slant angle and other relevant information.

Learn more here: https://www.scorpionvision.co.uk/blog/labelling-cheese-wedges-with-a-3d-robotic-labeller